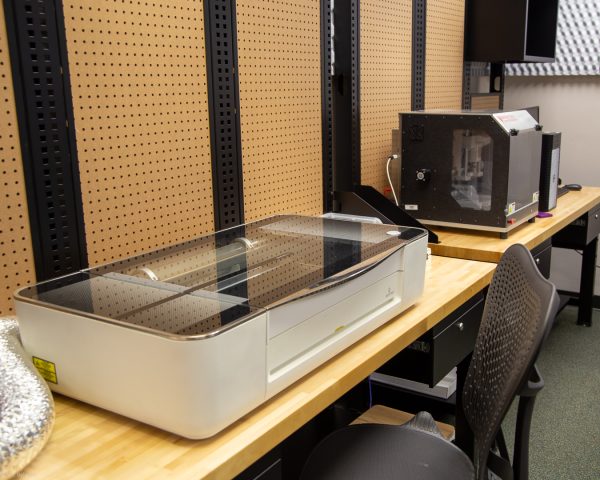

The MakerSpace is a new room in the FGCU library where all students and faculty can come to work on projects that turn something digital into something physical. This room offers 3D printing, laser printing and a CNC milling machine.

Matthew Losey is the creative commons lab coordinator for the FGCU library and oversees the MakerSpace. He has tested and used all the equipment in this room. This room is located in 119 West Library and is Losey’s office space.

“We are not major specific,” Losey said. “It does not have to be for a course, it could be for a personal project.”

Losey said there are plans to begin orientations for this new space at the end of September or early October. This will consist of an in-person orientation and then an online quiz to test the participants’ knowledge.

Bobby Coleman is a Digital Media Design major who learned about the library’s original MakerSpace which only had 3D printers. Coleman said with the first room, students could only send in prints but not personally work with the printers.

Coleman has an interest in prop printing and cosplay from Star Wars like Mandalorian armor and lightsaber hilts. He has used the printers and helped a fellow student with a project on the Glowforge. The Glowforge Pro is a laser printer that cuts and engraves various materials.

He does have plans for using the MakerSpace once he completes the orientation.

“I am looking into materials that can be used on cars,” Coleman said. “Starting with internal parts and I might create body kits.”

The 3D printers are Fused Deposited Modeling printers. Currently, there are three printers in the room connected to computers with Slicing software. This software turns 3D models into sliced layers for printing. The main plastic used for these printers is Polylactic Acid, known as PLA, but others can be used in the printer. One is polycarbonate which melts at a higher temperature. Losey said that they use this material to print out items for car parts. Also, Thermoplastic polyurethane, known as TPU, is a flexible filament that Losey is experimenting with.

Losey said the Glowforge Pro is a CO2 tube laser that burns almost any image that is on a computer. There are different modes that the Glowforge Pro can complete. First it can completely cut through some materials or it can do scoring. Losey said that the scoring setting is a light that does not engrave but burns the design. This printer can be used on wood, leather, cardboard, acrylic, paper at low settings and for engraving aluminum. Losey said the best material to use is proofgrade even though it is more expensive.

The Computer Numerical Control (CNC) milling machine uses computer code and drill bits to create designs into strong materials. Some of the materials that can be used in this machine are metals, Delrin, wax and wood. The CNC drills into materials to create designs through the computer programs that connect to it. Losey said that this machine is the most hands-on piece of equipment in the MakerSpace because the machine’s coding and drill bit need to be exact, or there will be an irreversible error. This machine can also do engravings.

Losey said that the best option for using these printers and machines is to bring in materials that you have purchased because the process will be free to those students and faculty. But if that is not an option, Losey will work with the person for pricing related to any materials used.